Electric Motors for Press Brakes: Technologies and Advantages

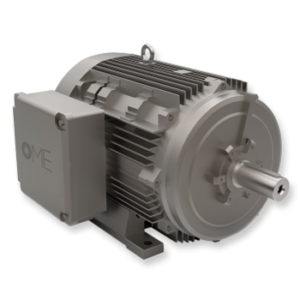

The current trend sees electric motors for press brakes as the go-to option in all highly automated and efficiency-oriented lines. The main advantages include:

- Extremely precise control of bending speed, stroke, and pressure.

- Structural energy savings, thanks to electronic regulation systems and energy recovery during braking.

- Drastic reduction in maintenance, due to fewer wear-prone parts compared to hydraulic alternatives.

- Ease of integration with supervisory software, industrial PLCs, and platforms for Industry 4.0.

These characteristics make the electric press brake motor the key to repeatable, fast, and customized processes, even on small batches and frequent production variations.

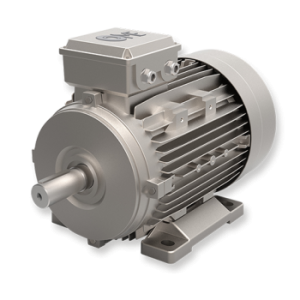

To get the most out of your press, the choice of a new electric motor for press brakes requires careful consideration of several factors:

- Power and torque: to be calibrated based on sheet thickness, hardness, and required cycles per hour.

- Control precision: crucial for repeated bends on complex or large pieces.

- Compatibility with the machine: checking installation spaces and connections to electronic controls.

- Reliability and maintenance: presence of self-diagnosis systems, quick access to spare parts, and technical support.

- Integration possibilities: communication with existing digital systems and future scalability towards Industry 4.0.

The consulting offered by our technical team always includes the assessment of real application data and the proposal of the optimal configuration based on the production cycle.

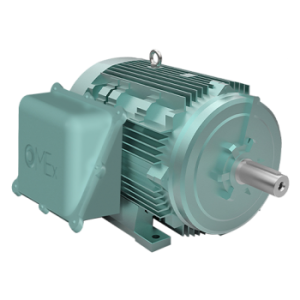

Selection and Customization: Solutions for Every Production Need

Every production facility has its own characteristics: some work on large thicknesses, others on quick small series, and others require frequent tool changes. That’s why our offer ranges from high-energy efficiency press brake motors, ideal for 24/7 production lines, to compact and high-performing solutions for medium-small workshops focusing on flexibility and minimizing downtime.

Modernizing a plant often doesn’t mean replacing it: retrofitting a press with a new electric motor not only enhances performance but also allows access to new levels of control through supervisory systems, remote assistance, and data collection. Upon request, we create custom configurations equipped with integrated sensors, automatic synchronization, and predictive maintenance management.

Fields of Application and Competitive Benefits

Press brakes equipped with the right electric motors find their place in various industrial sectors:

- Metalworking, for the production of profiles and structures.

- Automotive industry, where precise bends and very fast cycle times are required. Production of machinery and industrial equipment.

- Metal furniture and light metalworking, in cases where thin sheet metal is processed at high speeds.

The concrete benefits of choosing a high-performance motor reflect in:

- Reduction of consumption and operating costs.

- Increased production speed without sacrificing aesthetic quality.

- Improved overall reliability of the plant.

- Minimal extraordinary maintenance and maximum safety for operators.

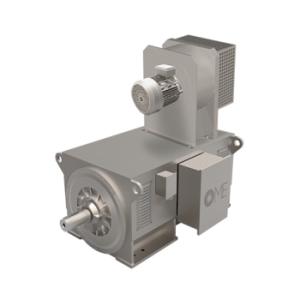

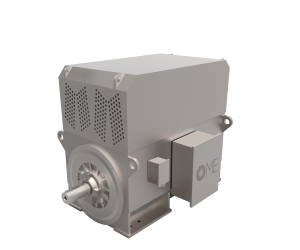

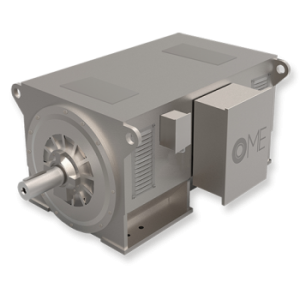

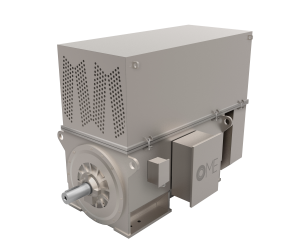

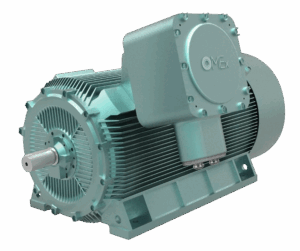

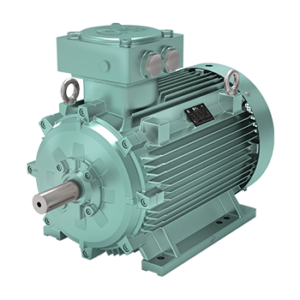

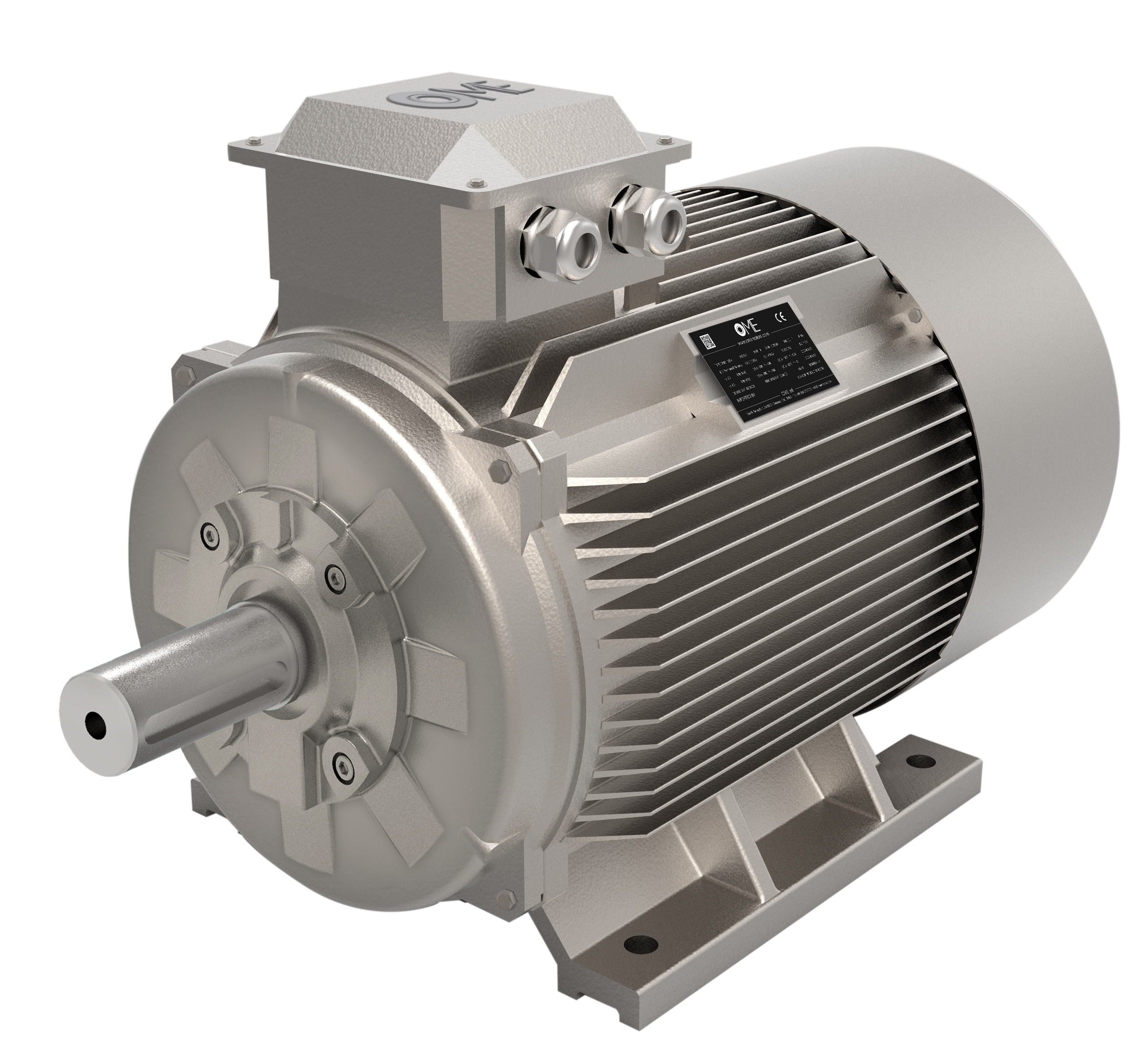

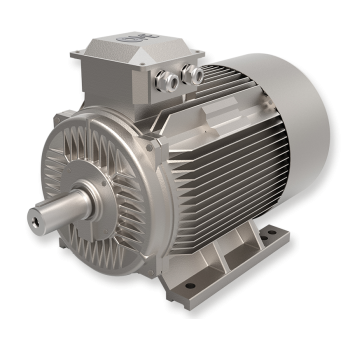

Updating your press brake begins with choosing a motor that defines its long-term performance. Whether you are designing a new plant or considering the revamping of an established line, OME Motors is the reference manufacturer for electric motors for press brakes capable of translating every technical need into real value. Discover our range, request a custom consultation, and immediately improve the efficiency, quality, and profitability of your production.

![]()