Types and Characteristics of Motors for Rolling Mills

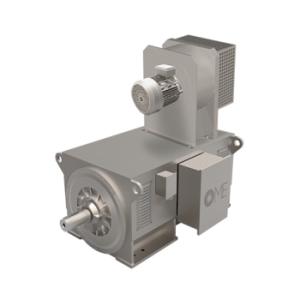

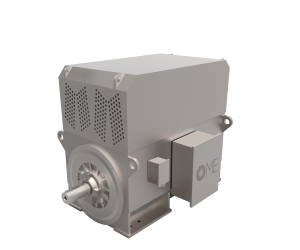

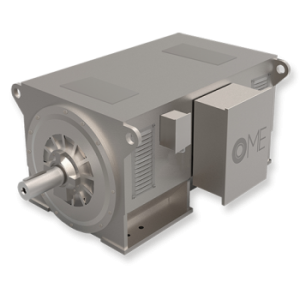

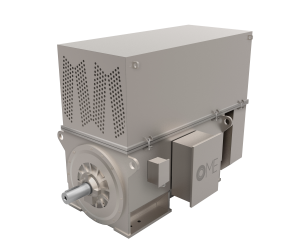

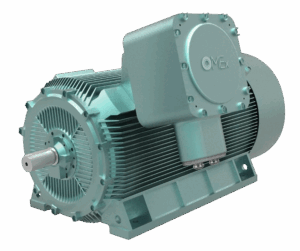

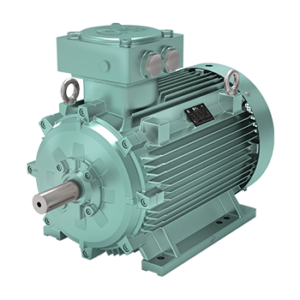

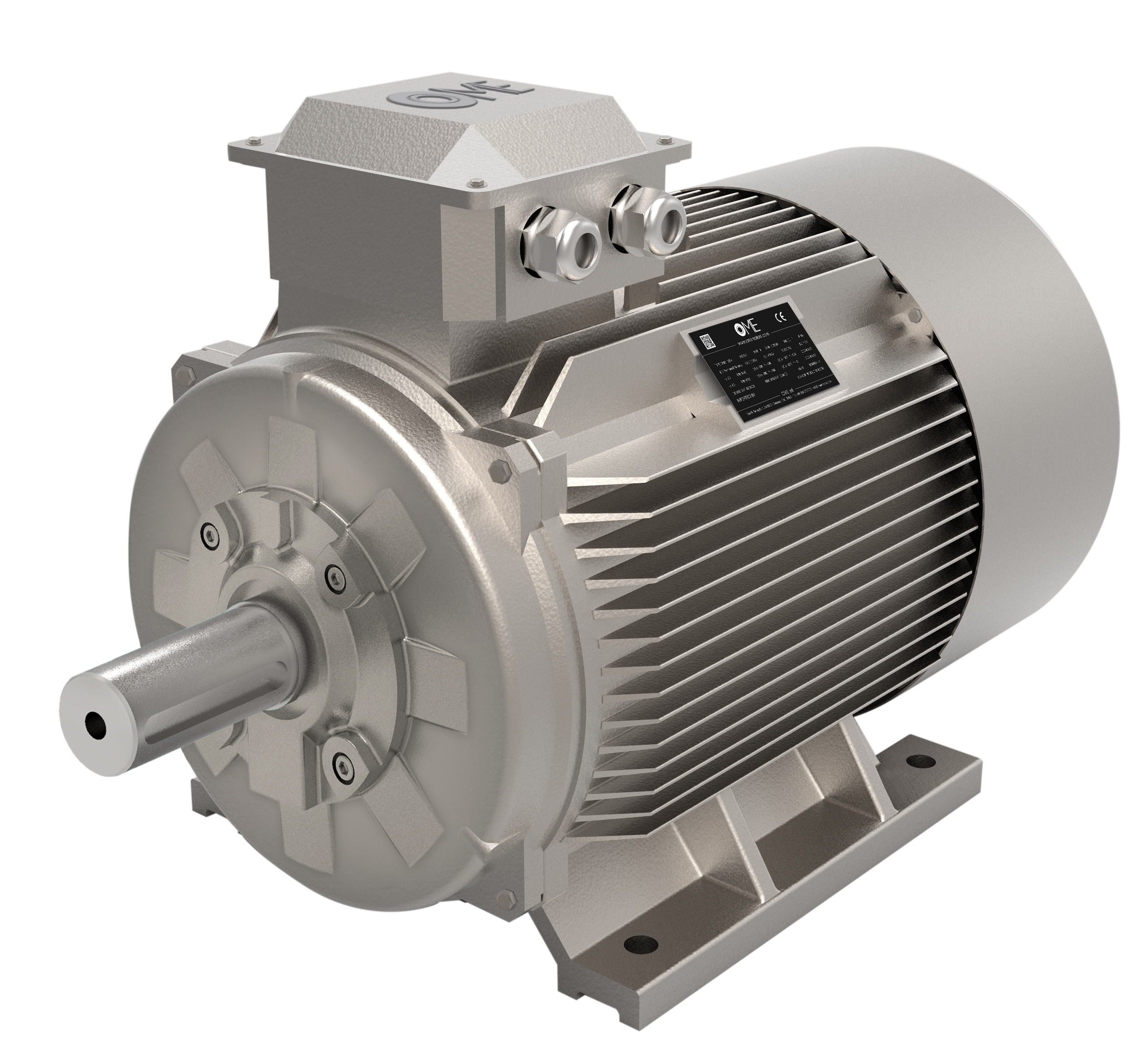

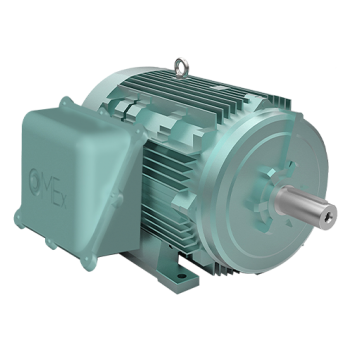

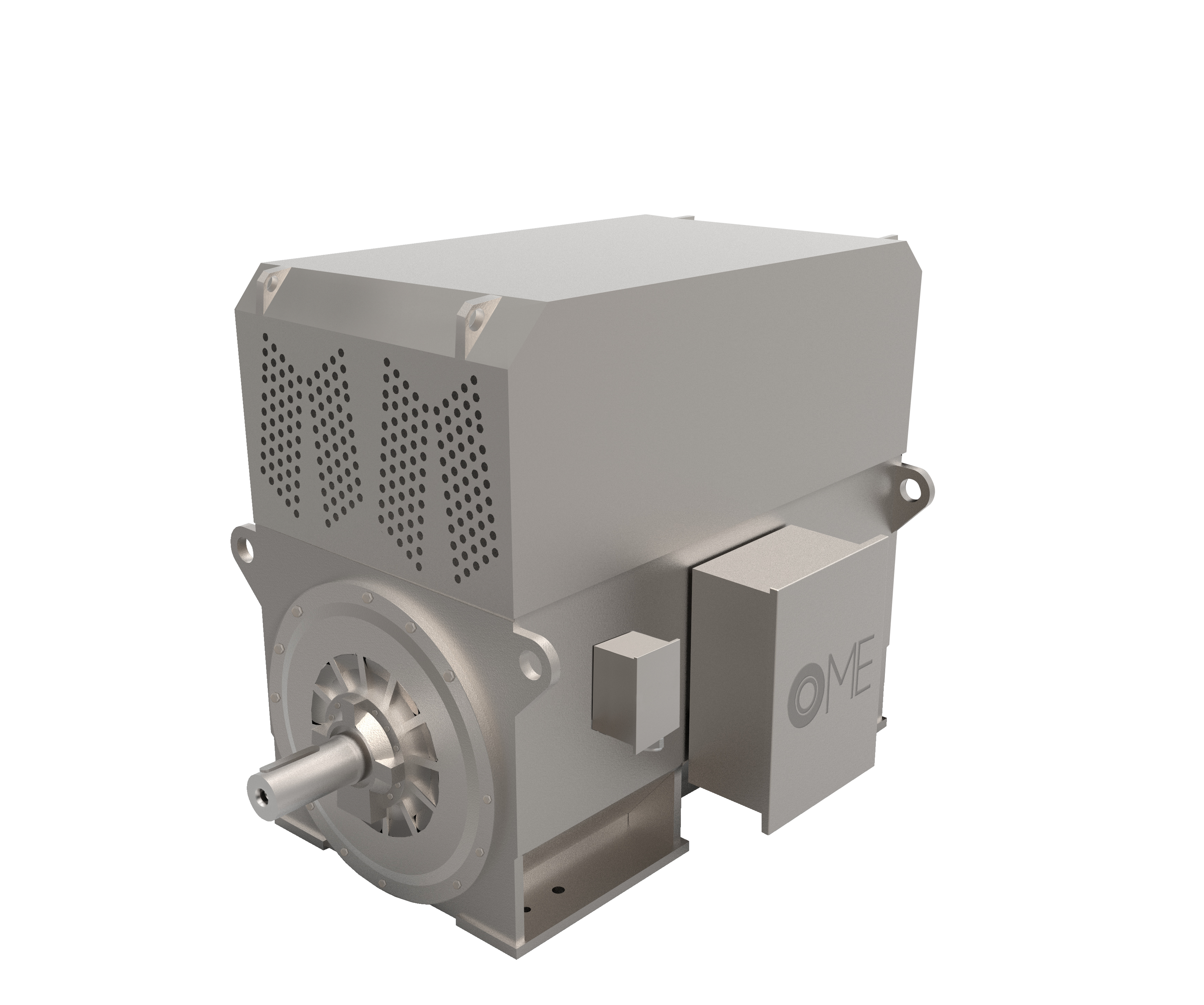

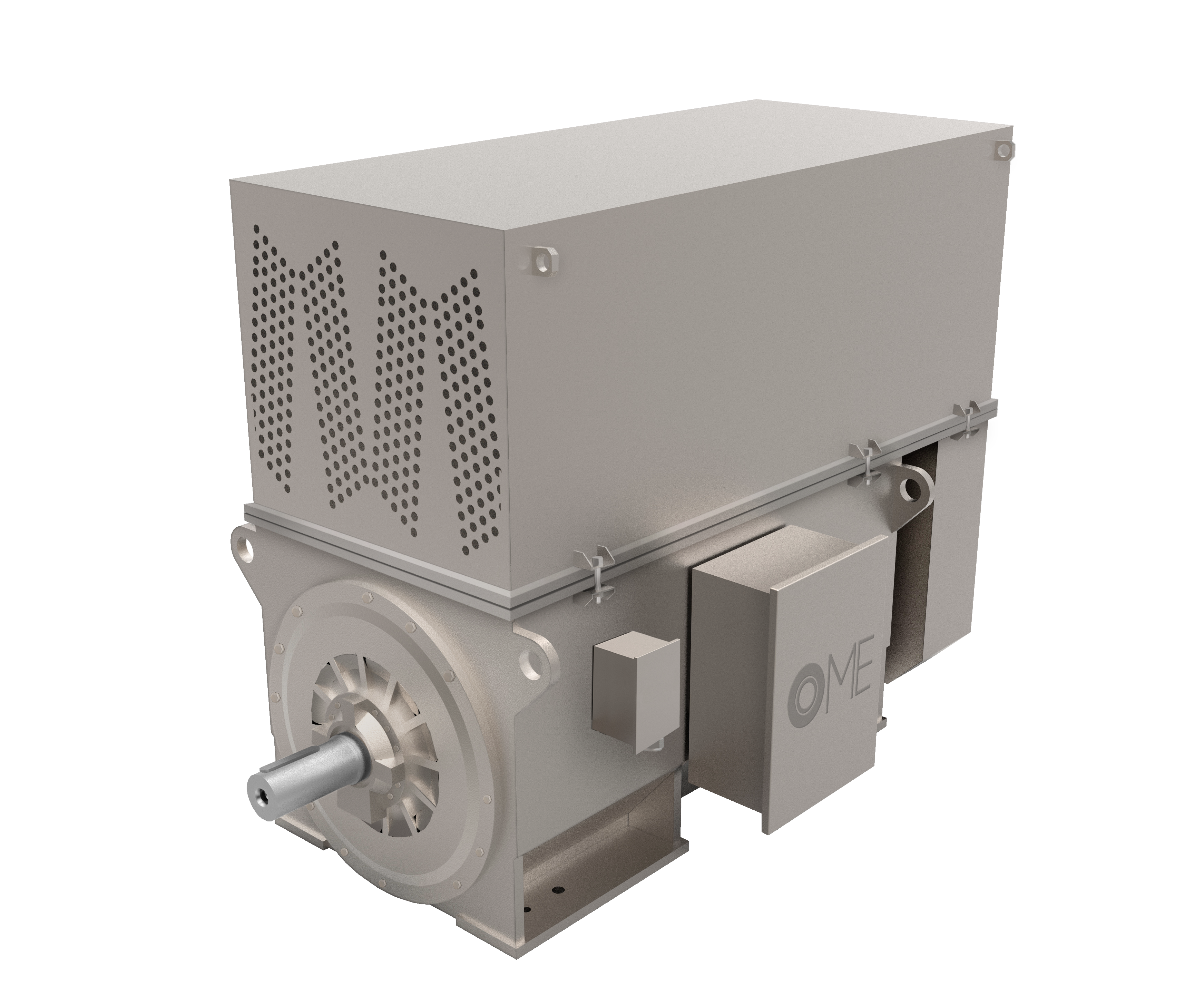

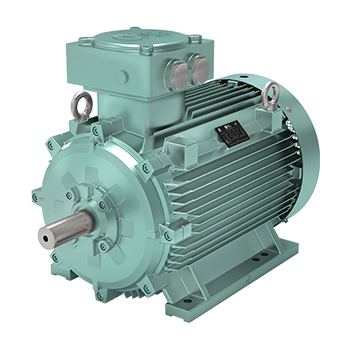

Each OME Motors rolling mill motor is the result of careful design and selection of materials intended to operate even under the most extreme conditions.

In our catalog, you will mainly find:

- Electric motors for mills: They offer high efficiency, precise speed control, and ease of integration into industrial automation systems. They are essential for those who aim for reliable process control and significant reductions in consumption.

- DC motors: Selected for their operational versatility and ability to provide high torque even at low speeds. Essential in lines where speed variability is a non-negotiable requirement.

- Induction and synchronous motors: Designed to work under harsh conditions and handle intense production cycles, these motors are synonymous with durability and robustness.

The available configurations allow us to meet differentiated power requirements, from small mills intended for detail work to large-scale steel plants.

Steel Plant Motors: Selection Criteria and Fundamental Parameters

Relying on a steel plant motor means selecting a solution that will support production activities for years. Some parameters must always be evaluated:

- Power and stress resistance: The motor must guarantee consistent performance even under prolonged stress or sudden load spikes.

- Energy efficiency: The most advanced technologies enable the reduction of consumption, containment of costs, and compliance with energy efficiency regulations.

- Electronic control: The presence of digital regulation and diagnostic systems allows for constant optimization of cycles and rapid identification of any anomalies or performance drops.

- Ease of maintenance: Motors designed for easy monitoring, overhauling, and updating, with guaranteed availability of original spare parts in reliable timing.

- Adaptability to environmental conditions: Degree of protection, thermal shields, and reliability even in the presence of dust and high temperatures.

These elements help reduce the risk of plant downtime and ensure continuous production, a key aspect especially in plants operating on a continuous cycle.

Innovation and Automation in Motors for Rolling Mills

In the steel sector, the trend towards automation is now the norm. Modern motors integrate seamlessly into advanced control systems, allowing for centralized management of processes and the possibility of implementing predictive maintenance strategies. This results in fewer interruptions, enhanced safety for personnel, and optimized productivity.

Reduction of environmental impact: The efficiency of new motors significantly cuts consumption and waste, contributing to a more eco-sustainable supply chain. Customization: The ability to configure motors tailored for specific production processes or for integration into existing plants.

Motors for Steel Plants: Applications and Sectors of Use

The range of motors for steel plants we offer finds application in various areas of the metallurgical and steel sectors. Some typical uses include:

- Hot rolling lines: where the power requirement and resistance to high temperatures are predominant.

- Cold mills: for high-precision processing and control over surface finish.

- Metal cutting and drawing: shaping processes that require rapid speed changes and reliability.

- Production of tubes and profiles: sectors where continuous and repetitive cycles demand consistent performance.

- Annealing and heat treatment plants: which integrate motors for controlled movement during the most delicate phases.

Depending on the application, we provide specialized consulting in selecting the most efficient rolling mill motor for productivity, quality, and cost containment. Additionally, OME Motors electric motors are certified according to the latest safety and sustainability regulations, and we offer the possibility of configuring custom solutions tailored to the specific parameters of each client. Transparency in quotes and rapid availability of spare parts are our distinctive standards: every client is supported by a consultant who evaluates not only immediate needs but also the growth prospects of the plant.

In a highly competitive sector like steelmaking, the efficiency of the plant hinges on the selection of each individual component. Rolling mill motors are the cornerstone of modern production lines: selecting the most suitable model and relying on a specialized partner in the production of industrial electric motors, such as OME Motors, makes the difference between stable production and one subject to unforeseen issues.

Trust in our experience and let our specialized offer guide you. For further technical details, quotes, and customized requests, our team is at your disposal, contact us.

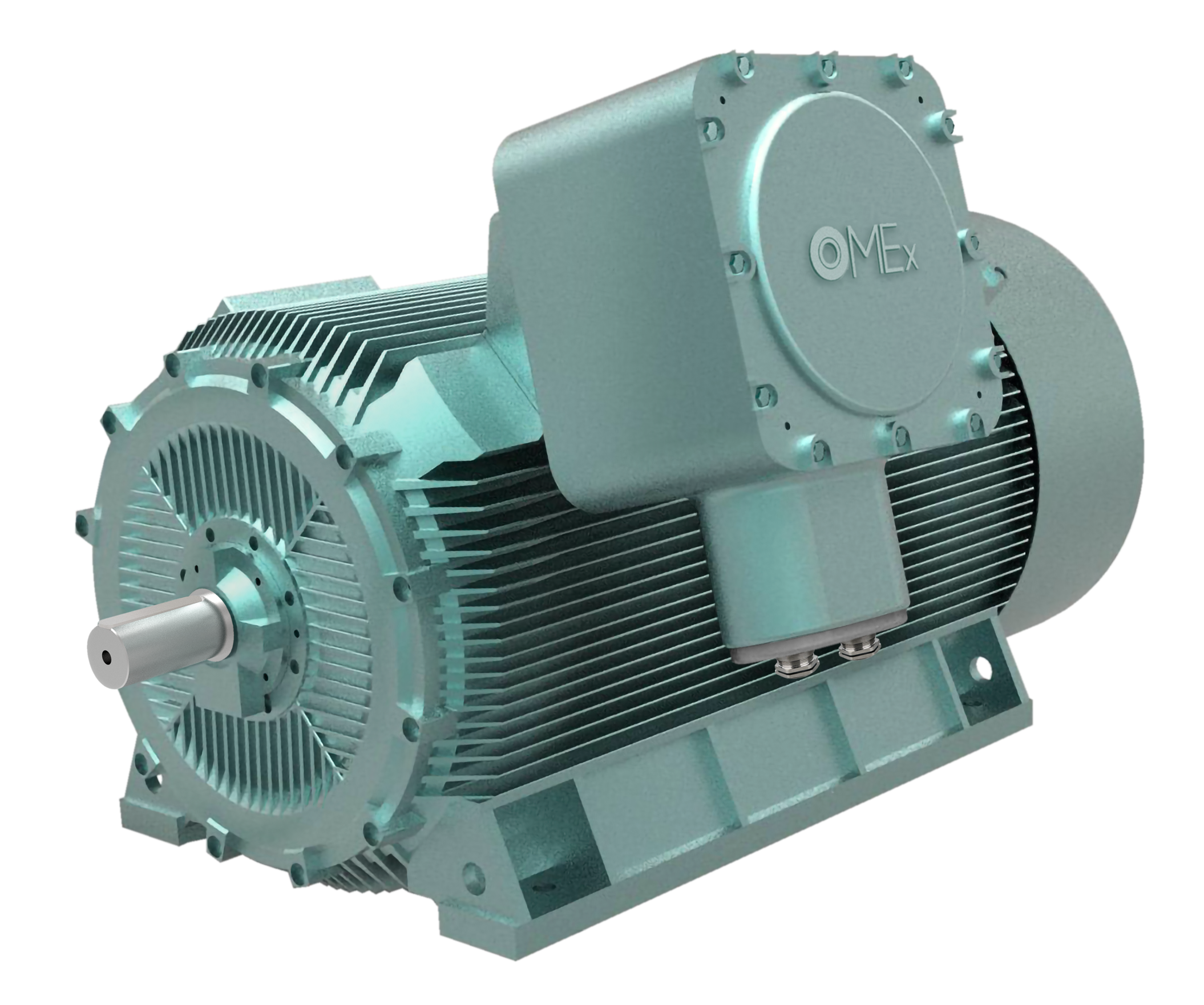

The steel industry and metalworking are sectors that do not allow for compromises: here, precision, efficiency, and the continuity of production processes are determining factors for competitiveness. Rolling mill motors represent the invisible yet fundamental heart of these industrial plants. They are responsible for the precise handling of materials at extremely high temperatures, the regularity of work cycles, the safety of operators, and ultimately, the quality of the finished product.

For rolling mills, choosing the right motor is a strategic decision that goes far beyond the mere installation of a component. It means committing to lean production, minimal essential maintenance, and a safe, sustainable production cycle.

OME Motors is a benchmark in the manufacturing of steel plant motors, carefully selected to deliver high-level performance at every stage of metalworking. We understand that the variety of industrial processes requires a specific response to each different need. Among the rolling mill motors OME Motors, you can find solutions designed for every type of mill, from cold drawing to large hot rolling lines. The goal is to ensure the reliability and flexibility necessary to promptly respond to ever-evolving demands.

Types and Characteristics of Motors for Rolling Mills

Each OME Motors rolling mill motor is the result of careful design and selection of materials intended to operate even under the most extreme conditions.

In our catalog, you will mainly find:

- Electric motors for mills: They offer high efficiency, precise speed control, and ease of integration into industrial automation systems. They are essential for those who aim for reliable process control and significant reductions in consumption.

- DC motors: Selected for their operational versatility and ability to provide high torque even at low speeds. Essential in lines where speed variability is a non-negotiable requirement.

- Induction and synchronous motors: Designed to work under harsh conditions and handle intense production cycles, these motors are synonymous with durability and robustness.

The available configurations allow us to meet differentiated power requirements, from small mills intended for detail work to large-scale steel plants.

Steel Plant Motors: Selection Criteria and Fundamental Parameters

Relying on a steel plant motor means selecting a solution that will support production activities for years. Some parameters must always be evaluated:

- Power and stress resistance: The motor must guarantee consistent performance even under prolonged stress or sudden load spikes.

- Energy efficiency: The most advanced technologies enable the reduction of consumption, containment of costs, and compliance with energy efficiency regulations.

- Electronic control: The presence of digital regulation and diagnostic systems allows for constant optimization of cycles and rapid identification of any anomalies or performance drops.

- Ease of maintenance: Motors designed for easy monitoring, overhauling, and updating, with guaranteed availability of original spare parts in reliable timing.

- Adaptability to environmental conditions: Degree of protection, thermal shields, and reliability even in the presence of dust and high temperatures.

These elements help reduce the risk of plant downtime and ensure continuous production, a key aspect especially in plants operating on a continuous cycle.

Innovation and Automation in Motors for Rolling Mills

In the steel sector, the trend towards automation is now the norm. Modern motors integrate seamlessly into advanced control systems, allowing for centralized management of processes and the possibility of implementing predictive maintenance strategies. This results in fewer interruptions, enhanced safety for personnel, and optimized productivity.

Remote monitoring: Intelligent management of operating parameters through digital interfaces, with automatic reports and timely notifications. Reduction of environmental impact: The efficiency of new motors significantly cuts consumption and waste, contributing to a more eco-sustainable supply chain. Customization: The ability to configure motors tailored for specific production processes or for integration into existing plants.

Motors for Steel Plants: Applications and Sectors of Use

The range of motors for steel plants we offer finds application in various areas of the metallurgical and steel sectors. Some typical uses include:

- Hot rolling lines: where the power requirement and resistance to high temperatures are predominant.

- Cold mills: for high-precision processing and control over surface finish.

- Metal cutting and drawing: shaping processes that require rapid speed changes and reliability.

- Production of tubes and profiles: sectors where continuous and repetitive cycles demand consistent performance.

- Annealing and heat treatment plants: which integrate motors for controlled movement during the most delicate phases.

Depending on the application, we provide specialized consulting in selecting the most efficient rolling mill motor for productivity, quality, and cost containment. Additionally, OME Motors electric motors are certified according to the latest safety and sustainability regulations, and we offer the possibility of configuring custom solutions tailored to the specific parameters of each client. Transparency in quotes and rapid availability of spare parts are our distinctive standards: every client is supported by a consultant who evaluates not only immediate needs but also the growth prospects of the plant.

In a highly competitive sector like steelmaking, the efficiency of the plant hinges on the selection of each individual component. Rolling mill motors are the cornerstone of modern production lines: selecting the most suitable model and relying on a specialized partner in the production of industrial electric motors, such as OME Motors, makes the difference between stable production and one subject to unforeseen issues.

Trust in our experience and let our specialized offer guide you. For further technical details, quotes, and customized requests, our team is at your disposal, contact us.

![]()