Electric Motors for Injection Molding Presses: Types, Innovation, and Technical Characteristics

The market offers a wide range of motors suitable for various types of molding machinery. The main distinctions concern the power source and the degree of technological innovation.

Electric motors for injection molding presses: now widespread in the most modern production lines, these motors are chosen when precision in movements, significant reductions in energy consumption and high performance are required even on very rapid production cycles. An electric motor for injection molding press stands out for its quietness, low maintenance costs and regulation capacity.

The choice between these solutions depends on the specific production, the type of polymers treated, the tolerances required on the molded parts and the automation logic of each department.

Injection Molding Press Motor Features

The motor for press used for injection molding must meet precise criteria, which directly affect the production aspects:

- Digital control and regulation: the new generation motors are compatible with sophisticated software and guarantee interfacing with the main PLCs in the sector.

- Torque and power: parameters to be valued in relation to the molten mass to be moved, the injection pressures required and the speed of the production cycles.

- Energy efficiency: in a context of increasing energy costs, electric motors for injection molding are increasingly sought after for their ability to reduce consumption without sacrificing performance.

- Quietness and compactness: an essential feature in new installations and in production departments that require controlled and comfortable working environments.

Innovation and Automation: The Competitive Advantage of Motors for Injection Molding

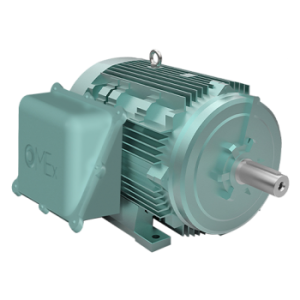

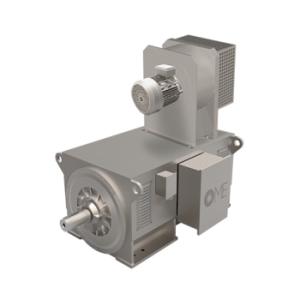

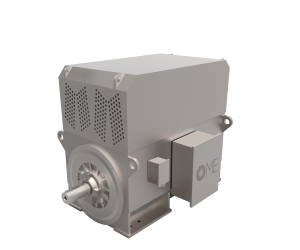

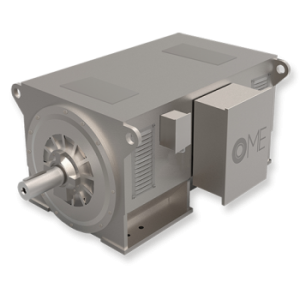

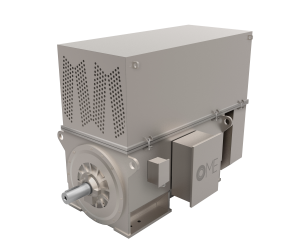

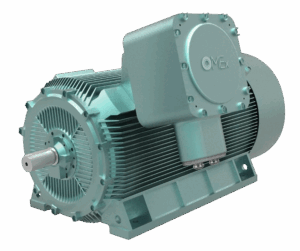

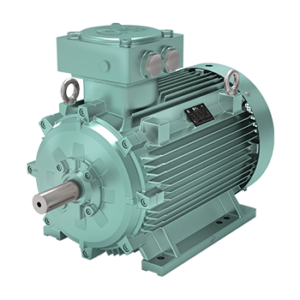

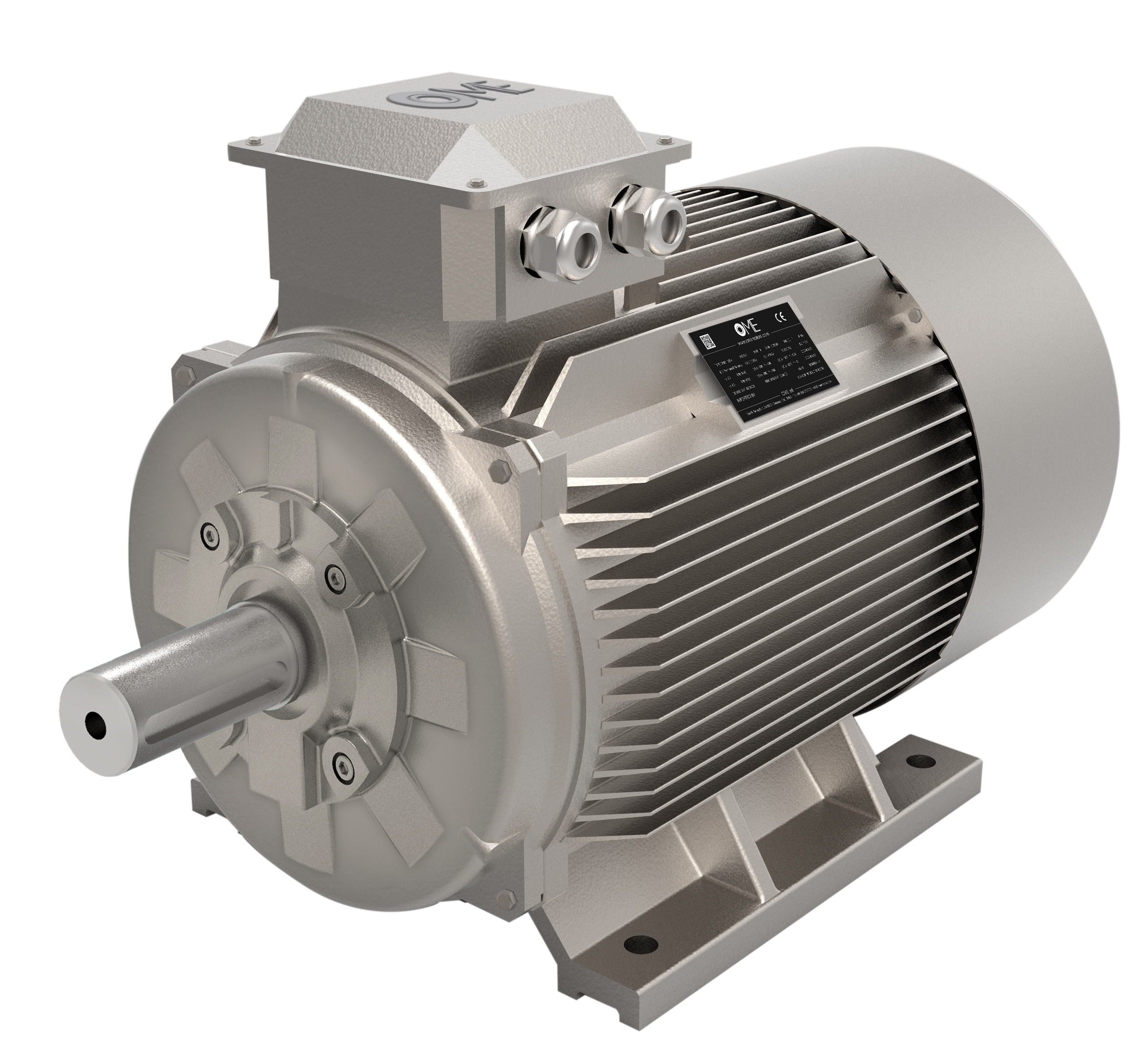

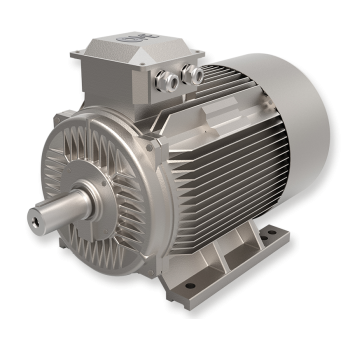

Automation and digitization are the paradigms of current production: OME Motors motors respond to Industry 4.0 logic and are the starting point for a high-performance, traceable and cost-optimized system.

Why Choose Electric Motors for Injection Molding Press

Electric motors for injection molding press are particularly appreciated for the following reasons:

- Extremely precise regulation of the movements of the injection unit and the screw

- Elimination of hydraulic leaks and the possibility of cleaner production environments

- Reduction of the overall temperature inside the department and the need for cooling

In many cases, the transition from the traditional hydraulic motor to the electric motor for injection molding press allows a drastic reduction in annual consumption and a return on investment in a rather short time.

Applications and Sectors Served by Motors for Injection Molding Presses

The application opportunities are countless, from the automotive world to electronics, from the medical sector to food packaging, up to technical and sporting goods. In each context, the choice of high-performance motors allows:

- Reduction of waste and non-compliance

- Better precision in details and tighter tolerances

- Greater productivity and speed of mold change

- Optimization of the range of workable materials (even the most technical and sophisticated plastics)

Most of the companies that aim for production excellence find an answer in OME Motors motors for latest generation injection molding presses, capable of adapting to the new challenges of global competition.

The electric motor for injection molding press is not only a technical component but the basis on which to build a stable and efficient production process. Investing in the right technology means ensuring superior results in every production, reducing consumption and lengthening the life of the machines. Discover the ideal OME Motors motor for injection molding press for your needs or request a customized consultation. The future of more efficient and sustainable plastic production starts here.

![]()