The Evolution of Air Conditioning Motors: Solutions and Types for Industry

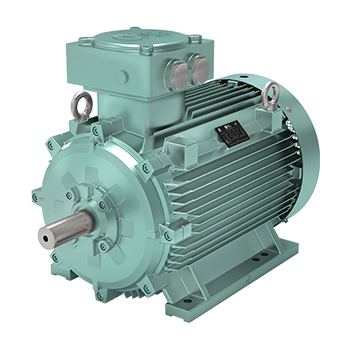

In modern industry, the air conditioning motor is no longer just a simple electromechanical component; it represents an integral part of a broader strategy aimed at ensuring controlled temperatures, smooth processes, and predictive maintenance. Understanding the features of different ducted air conditioning motors not only helps meet project parameters but also provides a competitive edge in terms of management costs and operational continuity.

Ducted Air Conditioning Motor: Technology and Benefits

More and more facilities are opting for ducted air conditioning solutions. A ducted air conditioning motor is designed to:

- Support high air flows through long duct runs

- Ensure temperature uniformity even in large warehouses or production departments

- Provide constant ventilation without excessive noise

- Integrate with centralized management and automation systems typical of Industry 4.0

Thanks to electronic control systems and high-strength materials, ducted air conditioning motors maintain high performance even in the presence of dust, humidity, or prolonged work cycles. They are ideal for applications requiring 24/7 reliability, such as automated warehouses, food production lines, laboratories, or process plants.

Air Conditioning Fan Motor: Specifications and Functions

The industrial air conditioning fan motor directly contributes to the efficiency of chillers, air handling units (AHUs), and multi-zone ducted systems, ensuring:

- A perfect balance between the air power moved and controlling consumption

- Quiet operation and reduced maintenance thanks to brushless technologies and long-lasting bearings

- Ease of integration into existing systems, due to a wide availability of universal and customizable models

- Motors for industrial ventilation: Focus on complex applications

A well-designed industrial air conditioning system takes into account not only the cooling and heating of air but also its proper circulation and purification. This is why ventilation motors play a crucial role:

- Forced ventilation motors, typically used for large refrigeration units, metrology rooms, controlled contamination environments, and production areas that generate heat or fumes.

- Motors for industrial chimney ventilation and primary air systems, as well as heat recovery or ventilation systems dedicated to the comfort of technical and control environments.

The ability to customize ducted air conditioning motors or ventilation systems allows for precise responses to real thermal and airflow needs, optimizing both energy management and the overall quietness of the system.

Applications and Competitive Advantages in Various Industrial Sectors

The versatility of industrial air conditioning motors allows for cross-sector use in manufacturing plants, logistics, large warehouses, electronics, pharmaceuticals, chemical industry, food, and any modern business requiring thermal control and air quality. In particular, ducted air conditioning motors find their place in:

- Continuous production areas, where maintaining temperature is critical for product quality.

- Warehouse areas with high merchandise turnover or industrial refrigeration, for the preservation of raw materials.

- Sensitive locations such as laboratories, control rooms, clean rooms for electronics or pharmaceuticals.

The advantages include:

- Energy optimization and cost reduction thanks to efficient motors and intelligent automation.

- Significant reduction in downtime due to breakdowns or unexpected maintenance.

- Improved indoor air quality, essential for operator safety and production quality.

- Continuous upgrade possibilities thanks to modular components and integration with new technologies.

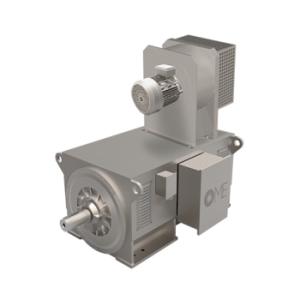

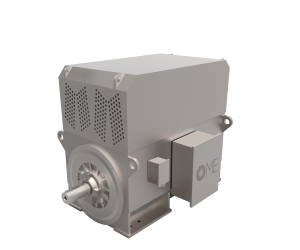

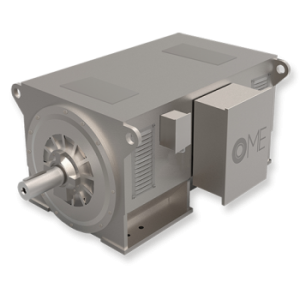

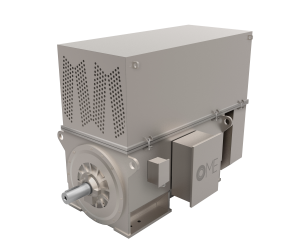

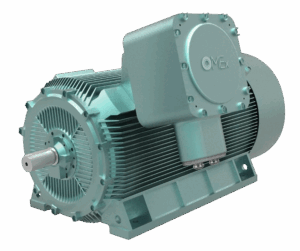

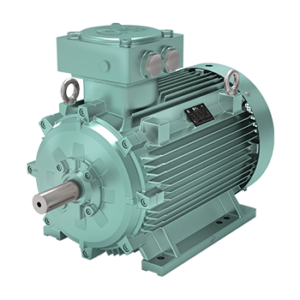

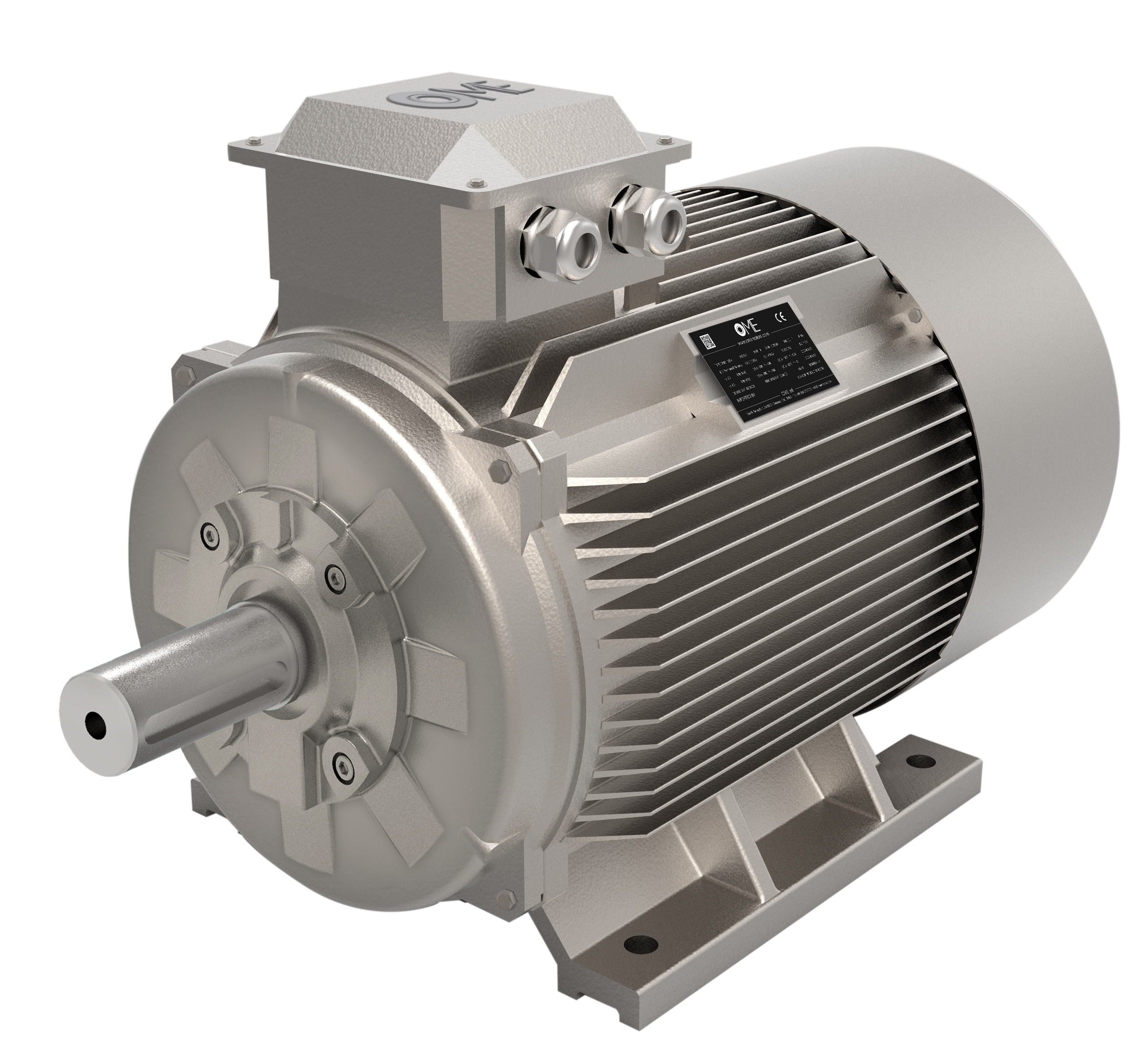

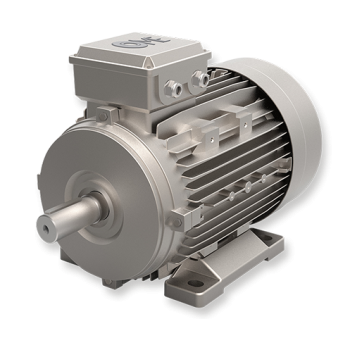

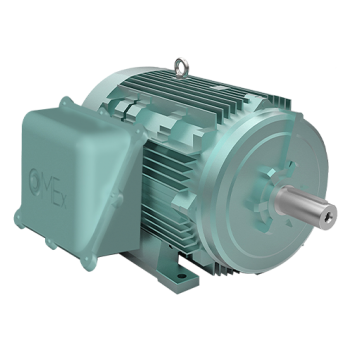

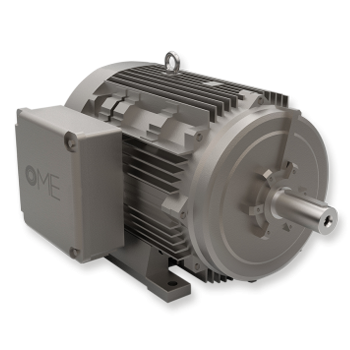

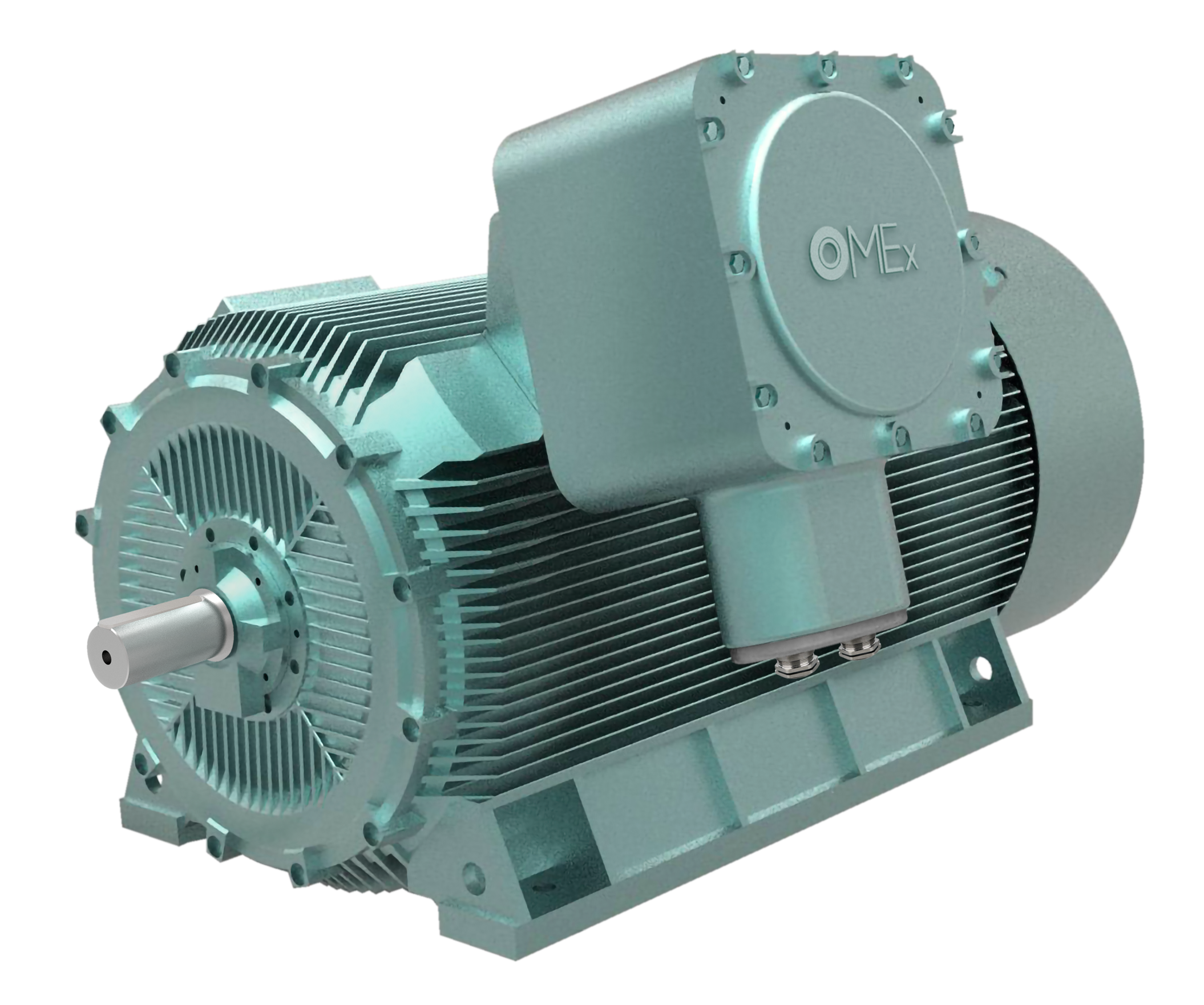

The industrial air conditioning motor is not just a technical component but a strategic investment for the competitiveness and safety of businesses. Relying on high-quality products, such as those from OME Motors, ensures reliable performance and controlled operating costs, even in the most demanding operational conditions. Discover the full range of air conditioning and ventilation motors on our website: our team of experts is always available to help you make the best choice, with tailored solutions for every production and technological need.

![]()