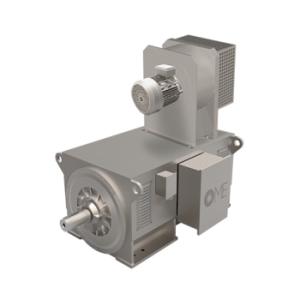

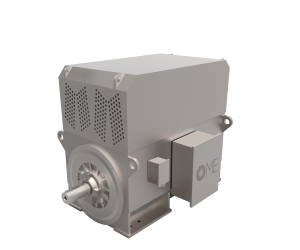

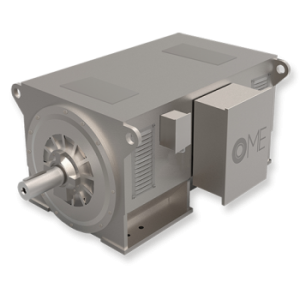

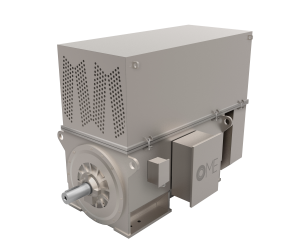

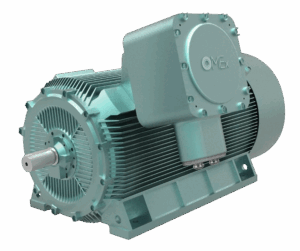

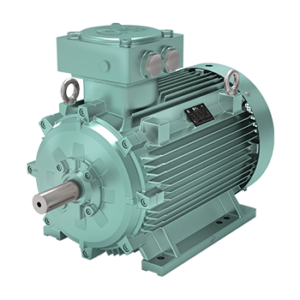

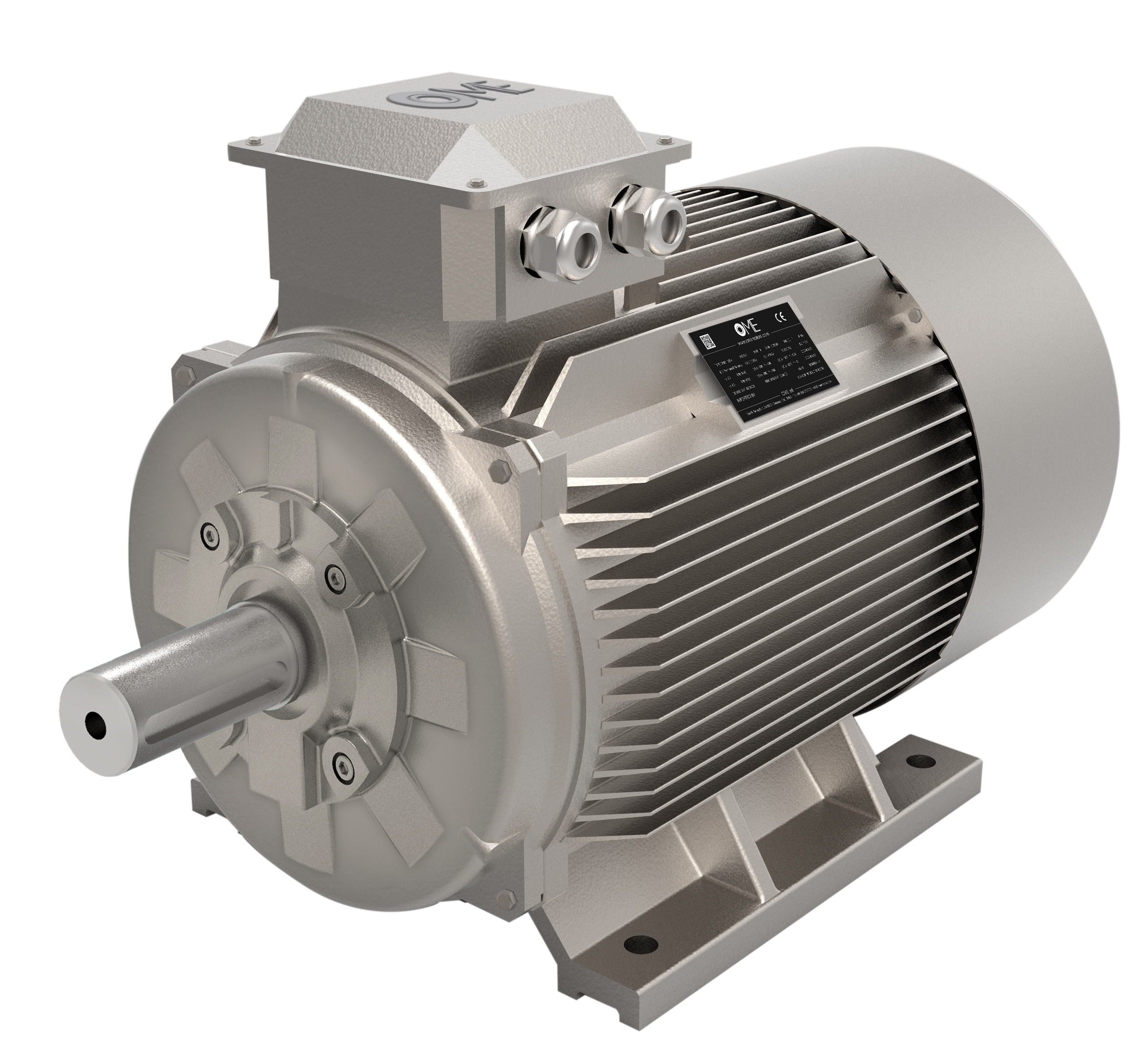

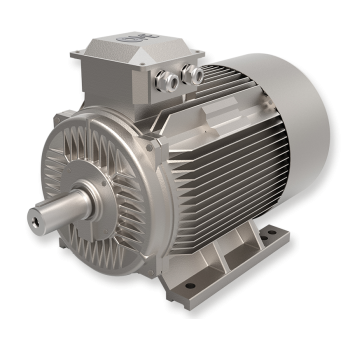

Types of Motors for Die Casting: Efficiency, Resistance, and Customization

In the world of die casting, the variety of processes requires motors with distinct characteristics. OME Motors electric motors are available in different types that differ in technology, capacity, and intended use. In particular, electric motors are preferred for the precision in regulating cycles, the speed of response and the simplicity of combination with automatic control systems. They allow high energy efficiency and guarantee low noise levels.

The choice of die casting motor must also take into account aspects such as the size of the system, production volumes, temperature control and compatibility with the latest generation of automation and software.

Technical Characteristics in Motors for Die Casting Machinery

A series of technical parameters determine the performance of a motor for die casting machinery:

-

- Rated power: The core of the dimensioning, it must be adequate to the operating load and the dynamic characteristics of the system.

- Energy efficiency: New global standards impose a careful assessment of consumption. Our selection includes premium class and eco-design motors for tangible long-term savings.

- Resistance to temperatures and contaminants: The injection, holding and mold opening phases often take place in harsh environments. The selected motors are made with materials and protections suitable for resisting dust, humidity, abrasive substances, and strong temperature variations.

- Control and automation: The latest generation **motors for die casting** are compatible with PLCs, industrial IoT systems and remote diagnostic software, increasing predictive maintenance and reducing intervention times.

- Reliability over time: All the motors for die casting machinery that we offer are subjected to structural tests and endurance tests, so as to offer a real guarantee on performance even after long cycles of use.

Innovation as a Lever of Competitiveness for Die Casting

The adoption of advanced motors allows companies to remain competitive in international markets. The latest trends range from energy saving — with low consumption and energy recovery models — to intelligent monitoring via integrated sensors that report in real time any anomalies or the need for maintenance. This allows production managers to optimize plant management and minimize the risks of downtime, unexpected costs, and defects.

Fields of Application of Motors for Die Casting: From Automotive to the Electronics Industry

Much of the innovation in modern industry passes through die casting. motors for die casting machinery are now used by leading companies in the following sectors:

- Automotive: For the production of structural components, mechanics and light housings that require intense production cycles and absolute reliability.

- Electronics and lighting: Where the miniaturization of parts is combined with the need for precision and reduced consumption.

- Furniture and home accessories: For the production of handles, fittings, design elements that must meet rigorous aesthetic and performance parameters.

- Aerospace and transport: Where weight reduction is associated with stringent quality and safety requirements.

In each of these areas, our motors for die casting allow you to maintain high production standards and lower the total cost of system management.

The needs of high value-added industrial sectors require attention, competence, and reliable solutions. Our motors for die casting, combined with the professionalism of our team of experts, are the guarantee of continuous production without surprises. Discover the solutions in the catalog, explore the technical data sheets and contact us to configure the ideal solution for your system. The future of more efficient die casting starts here.

![]()