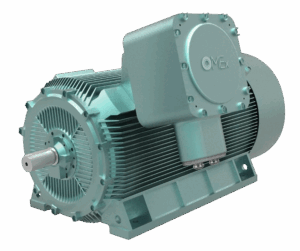

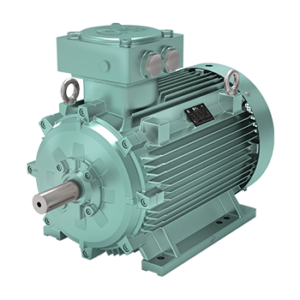

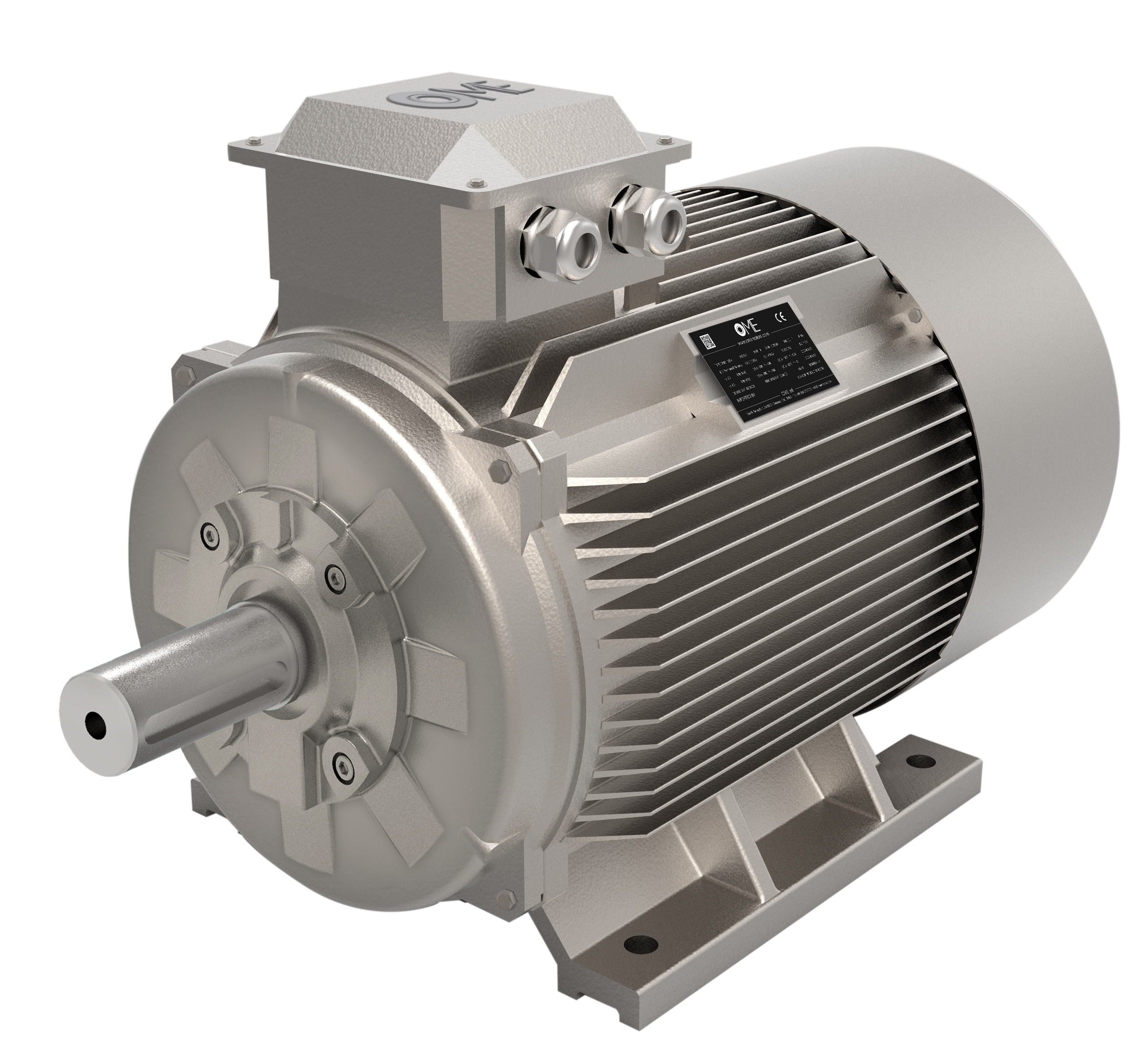

Electric Motor for Conveyor Belt: Features and Advantages

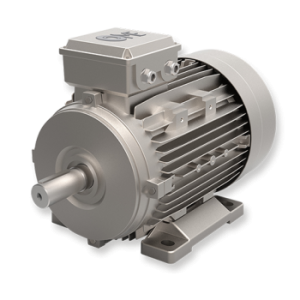

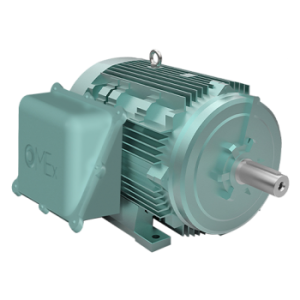

It is the most widespread and versatile solution, suitable for most modern industrial applications. The electric motor for conveyor belt offers:

- Excellent reliability and durability even in continuous operation

- High energy efficiency

- Easy speed control and regulation

- Perfect integration with automation systems and PLCs

- Availability of solutions for dusty, humid environments, and sectors with stringent hygiene requirements, such as the food sector

Electric motors for conveyor belts are designed to ensure low maintenance and rapid interventions in case of need, thanks to a structure that is often modular and accessible.

Hydraulic Motor for Conveyor Belt

In contexts where high power, rapid accelerations or resistance to particularly harsh environmental conditions are required, the hydraulic motor for conveyor belt represents a valid alternative. It is often chosen for:

- Applications in the extractive, mining and recycling sectors

- Large conveyor belts, subject to significant loads or sudden speed variations

- Environments where electrical solutions may be less reliable due to thermal shock or contamination

The control of these motors can be combined with automation systems, enabling integrated and flexible plant management.

A Conveyor Belt Driven by a Motor: Configurations and Modularity

Each application may require a specific solution: from belts driven by brushless motors for maximum precision, to direct current motors chosen for smooth speed regulation, up to custom systems in which the motor, sensors and control software are fully integrated.

The modular options adapt to different loads, transport profiles, inclinations, and extreme environmental conditions, guaranteeing total control over the handling of materials.

So that a conveyor belt driven by a motor is truly efficient and durable, it is essential to evaluate:

- Length and width of the belt

- Weight and type of material transported

- Slope of the path and presence of curves

- Required translation speed and hourly work cycles

- Environments of use: resistance to dust, liquids, chemical or sanitizing agents

- Necessary power and operating regime (continuous, intermittent)

Only an accurate analysis of these aspects leads to the selection of a motor for conveyor belt that meets expectations, minimizing the risk of inefficiencies, overheating, or sudden blockages.

Sector Applications: From the Food Industry to Logistics

Conveyor belts driven by a motor are applied in a variety of sectors:

- Food industry: safe transport of packaged products, raw materials or fresh food with ease of sanitation

- Logistics and warehousing: optimization of flows and reduction of handling times for pallets and materials on rollers

- Mining and recycling sector: handling of heavy, abrasive or loose materials over very long sections

- Packaging and internal handling: automated management of packaging, boxes and packages along different production lines

In each of these areas, choosing the right motor for conveyor belts means being able to count on productivity, safety and reduction of total management costs.

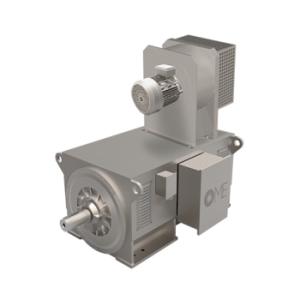

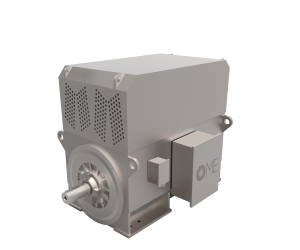

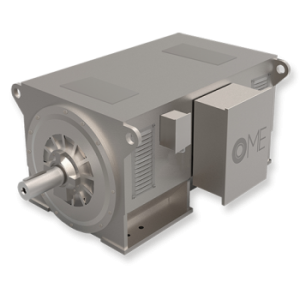

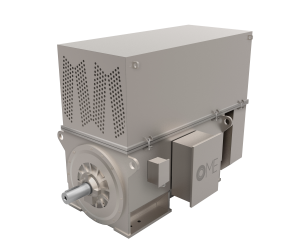

Choosing a motor for conveyor belt does not simply mean buying a component, but investing in the productivity and flexibility of the entire logistics and production chain. OME Motors only provides you with certified solutions, designed to guarantee efficiency, reliability and integration with the latest industrial technologies. Discover our selection of electric motors for conveyor belts, custom solutions now: our team is ready to guide you towards the most suitable configuration for your operational needs and your growth objectives.

![]()