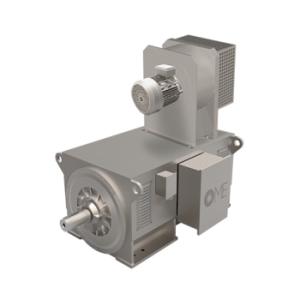

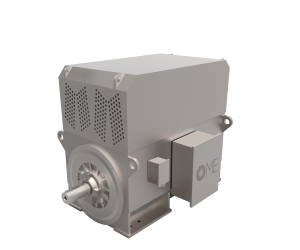

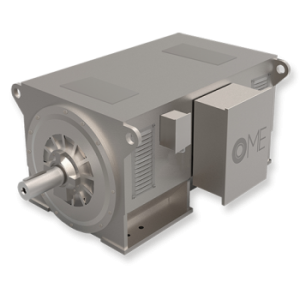

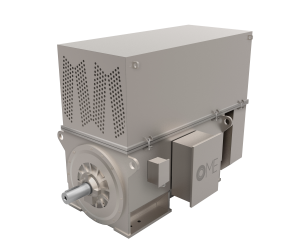

Types of Electric Motors for Compressors

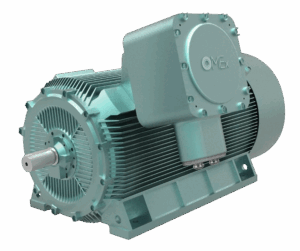

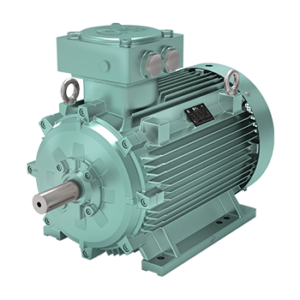

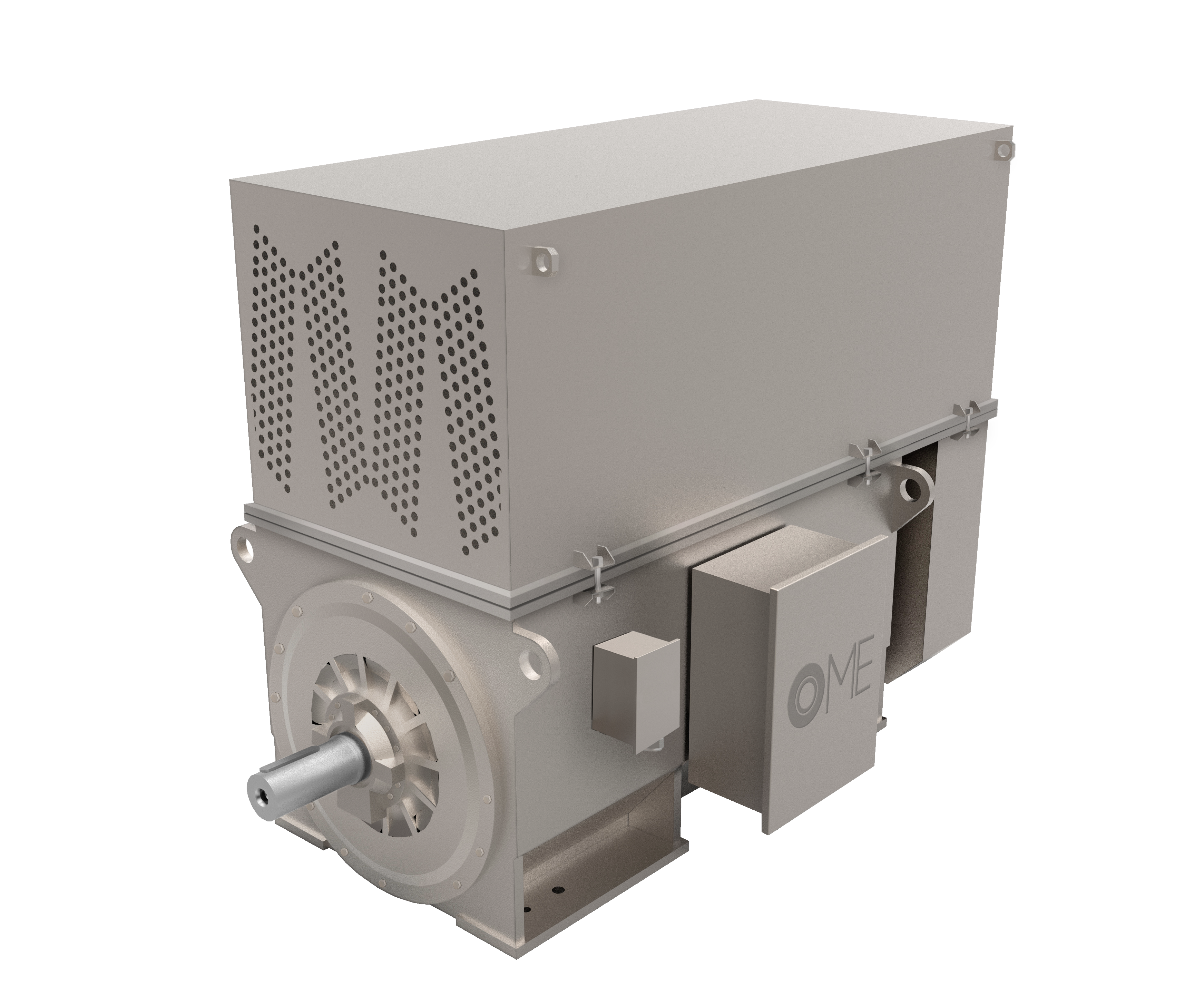

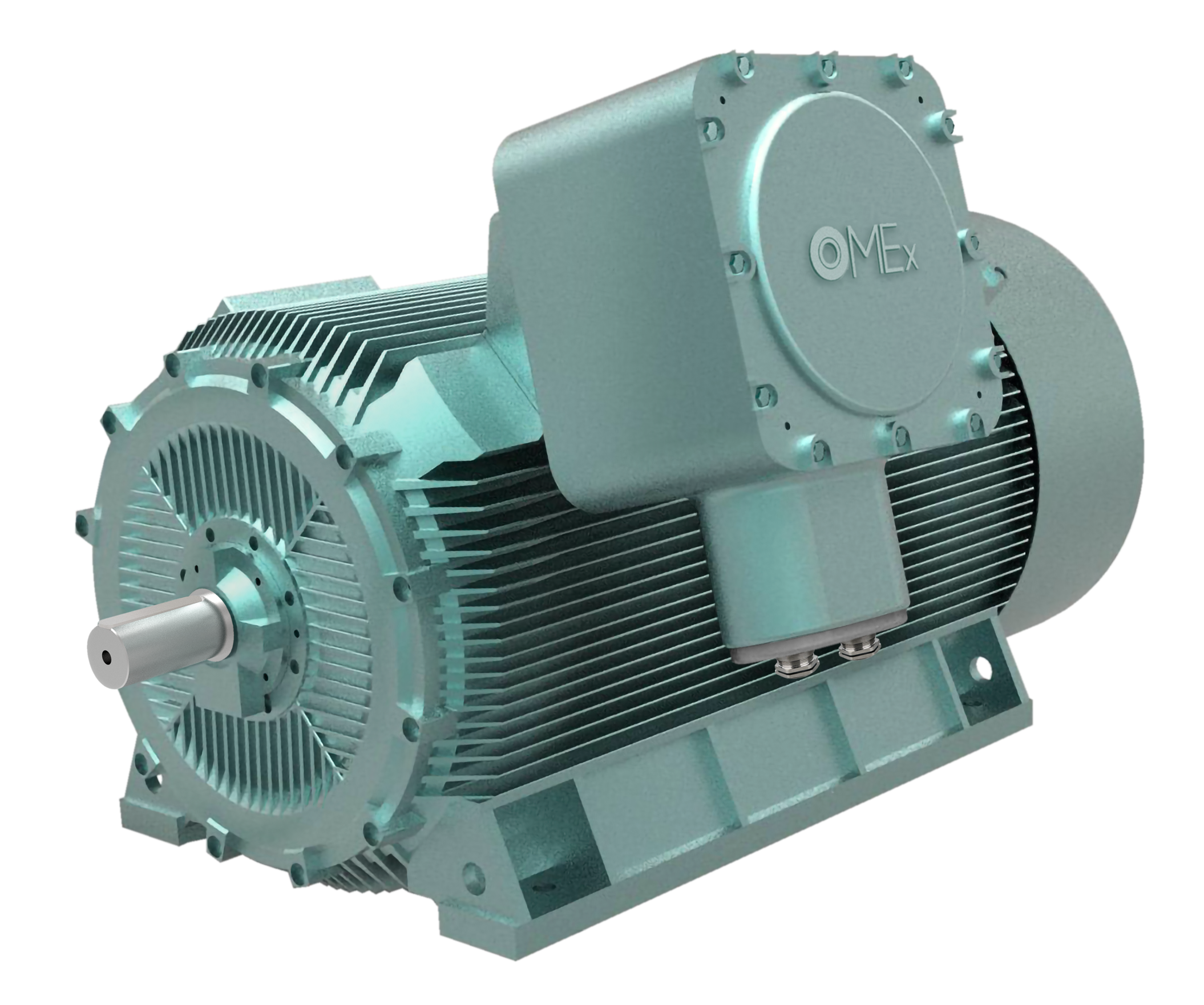

Electric Motor Compressor

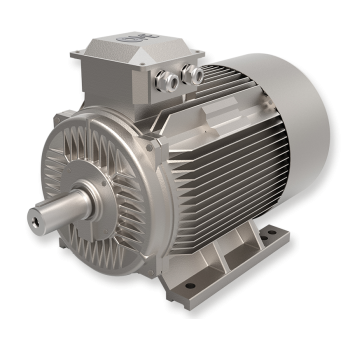

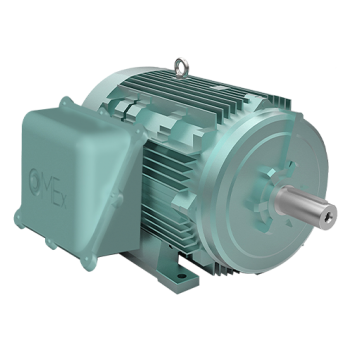

Electric motor compressors are among the most common due to their efficiency and reliability. These models are ideal for commercial use, offering easier maintenance compared to internal combustion engine compressors. A distinguishing feature is their ability to operate in enclosed spaces without the need for external ventilation.

- Electric motor for compressor: This type of motor significantly reduces noise, making the compressor more suitable for environments such as workshops and garages.

- Electric motor for 100-liter compressor: Ideal for applications requiring greater capacity, it ensures efficient airflow for industrial needs.

Internal Combustion Engine Compressor

Internal combustion engine compressors use fuel to operate and are particularly useful in outdoor settings where access to electricity is limited. These compressors are valued for their power, making them suitable for heavy-duty applications.

They provide high power and are perfect for construction sites or agricultural activities. However, they require more maintenance compared to electric models.

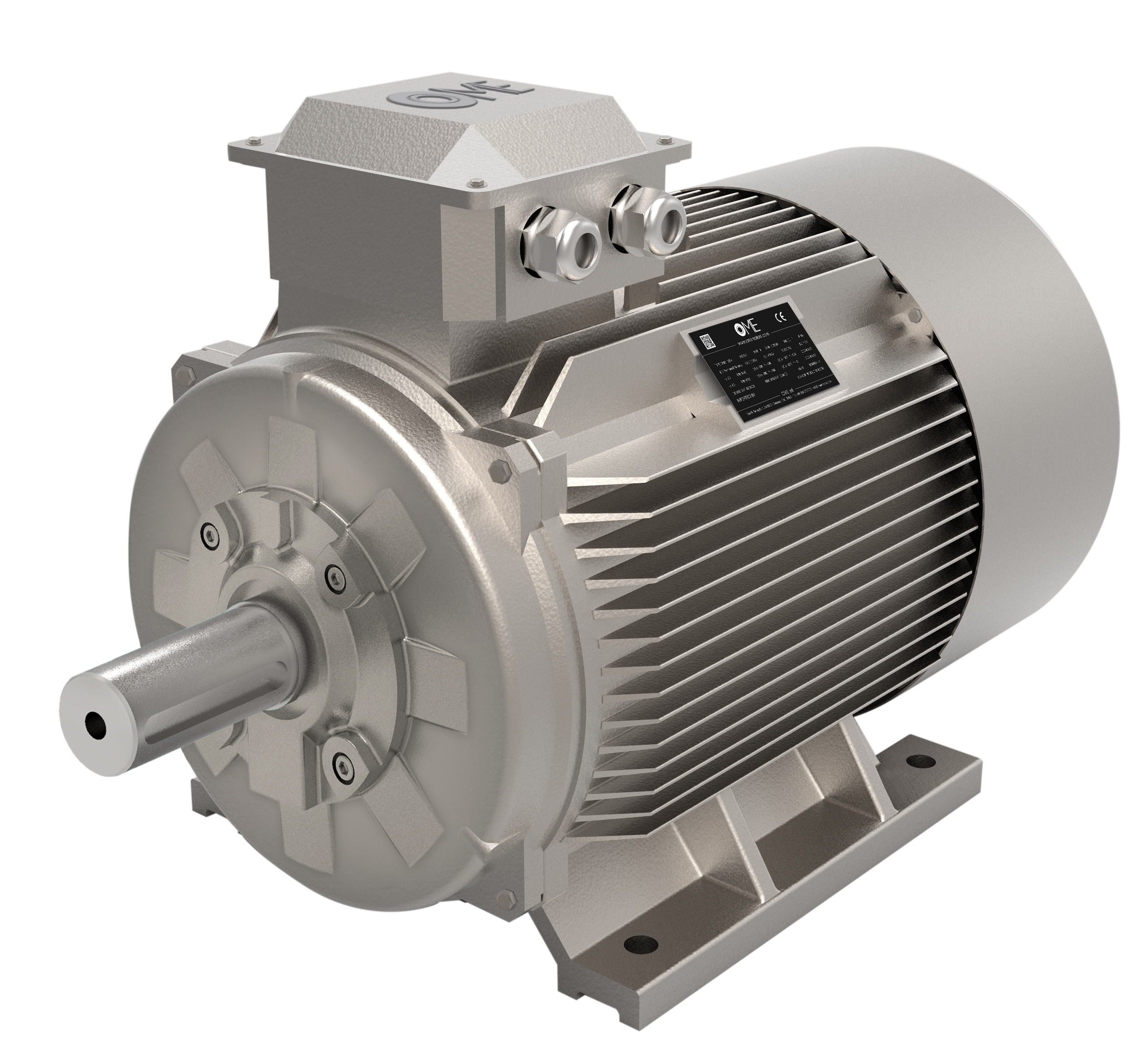

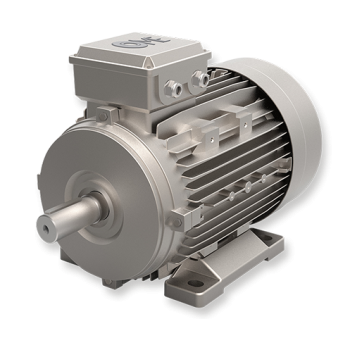

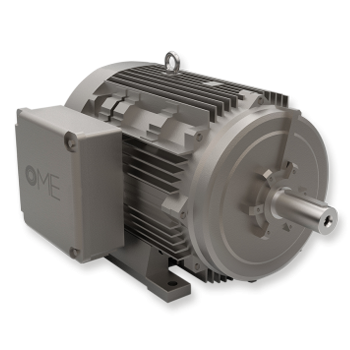

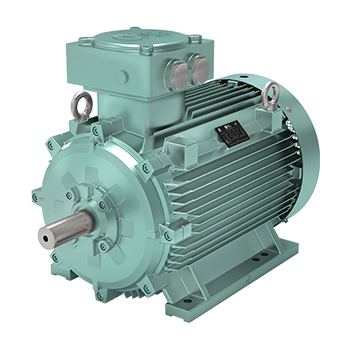

Single-phase Motor for Compressor

For lighter applications, the 2 HP single-phase motor for compressor is an excellent choice. These compressors are easy to install and offer a good balance between power and ease of use.

Perfect for small workshops or indoor use, thanks to their practicality and user-friendliness.

The choice of the right compressor depends on various factors, including intended use, budget, and available space. Consider these aspects:

- Capacity and power: Evaluate the tank capacity and motor power based on your specific needs.

- Portability: If you need to move the compressor frequently, consider lighter portable models.

- Energy efficiency: Opt for compressors with a good efficiency rating to save on operating costs.

For more information on compressor motors and to find the model best suited to your needs, contact our team of experts. We are ready to guide you in making the best choice to optimize your operations.

![]()