What is an industrial blower and why is the motor crucial?

An industrial blower is a device designed to generate an airflow or gas flow through a controlled system. It is widely used in wastewater treatment plants, ventilation processes for warehouses and production lines, pneumatic transport of powders, and other areas. Without a reliable industrial blower motor, these systems cannot guarantee either autonomy or consistent results over time. Therefore, the motor selection must be calibrated according to the specifics of the production cycle, the environmental conditions, and the required operating cycle.

Electric motor for industrial blower: advantages and applications

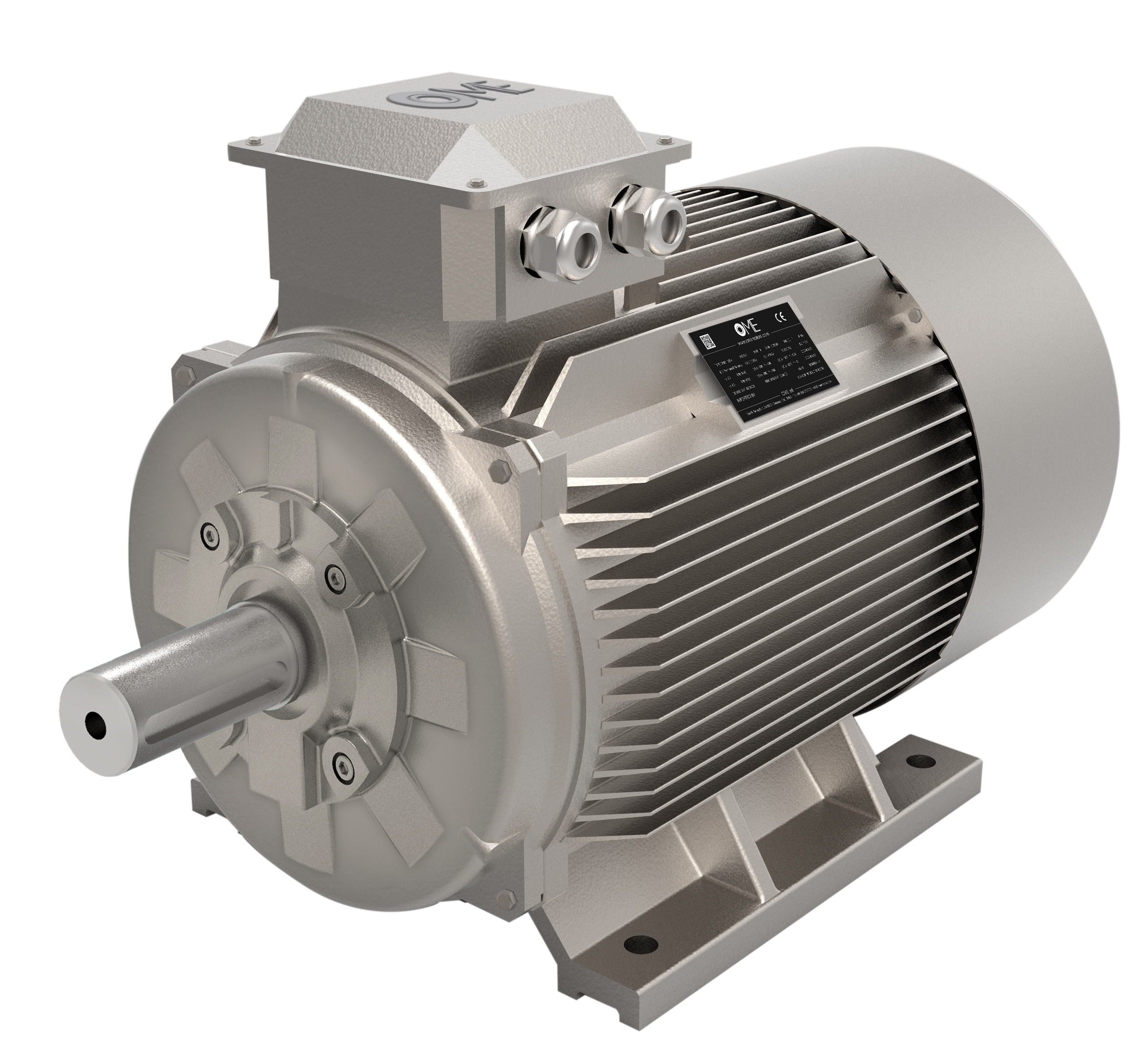

The electric motor for industrial blowers represents the standard reference for most modern applications due to a range of tangible benefits:

- High energy efficiency and reduced losses

- Ease of control and speed adjustment via inverters or digital systems

- Low maintenance costs and robust structure for continuous use

- Wide availability of solutions for every range of flow and pressure

Electric motors for industrial blowers also stand out for their ability to integrate with remote monitoring systems, centralized automation, and PLC control, laying the groundwork for an intelligent and advanced production management.

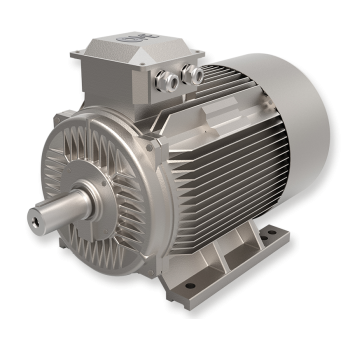

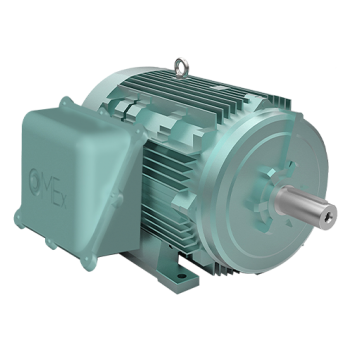

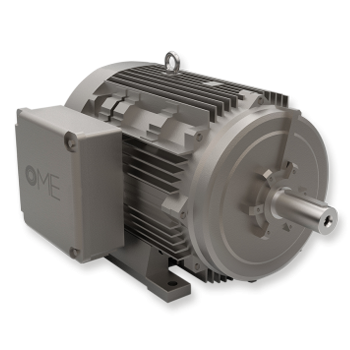

Electric motors for industrial blowers: variety of solutions

The range of electric motors for industrial blowers encompasses solutions for every demand regarding flow, pressure, and adaptability to the system. The main types and their strengths include:

- High-efficiency three-phase motors for large industrial systems

- Single-phase motors for light applications or environments with limited energy availability

- Tropicalized models, ideal for environments with high humidity, dust, gas, or extreme temperatures

- Customized solutions, built to specific requests, to ensure perfect compatibility and interoperability within the existing line

The ability to choose from various power levels, construction structures, and certifications (e.g., ATEX for explosion-risk areas) allows for extensive personalization of the entire system, increasing the competitiveness of businesses in the market.

Selection criteria for industrial blower motors

The choice of an industrial blower motor goes beyond just the nominal power rating. It is crucial to carefully evaluate:

- The required airflow and pressure from the blower

- The operating cycle: continuous, intermittent, with frequent starts and stops

- The environment in which the motor will be installed, to ensure durability against dust, chemical agents, or aggressive atmospheres

- The ease of integration with existing systems in the company, including automation and data collection tools

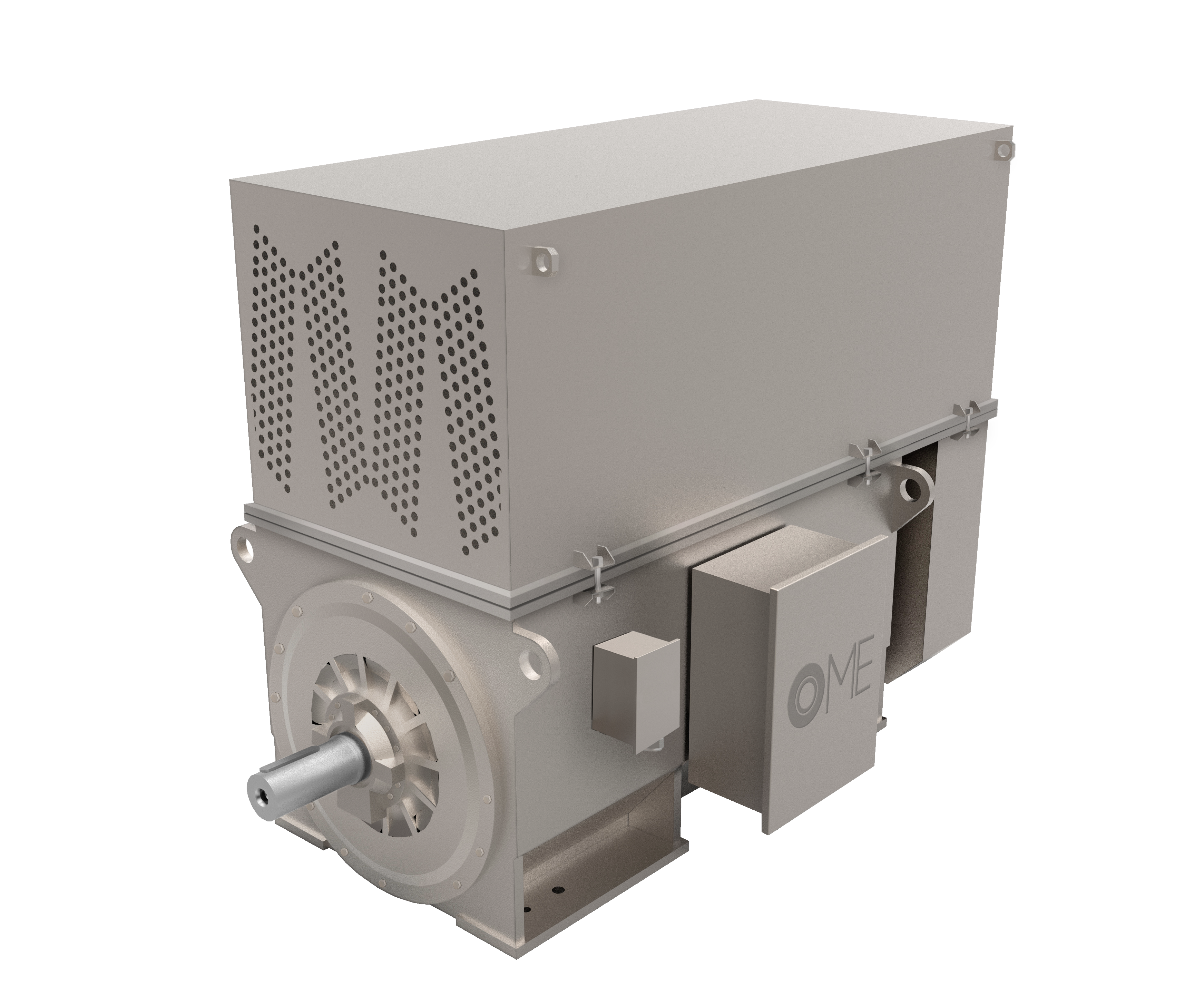

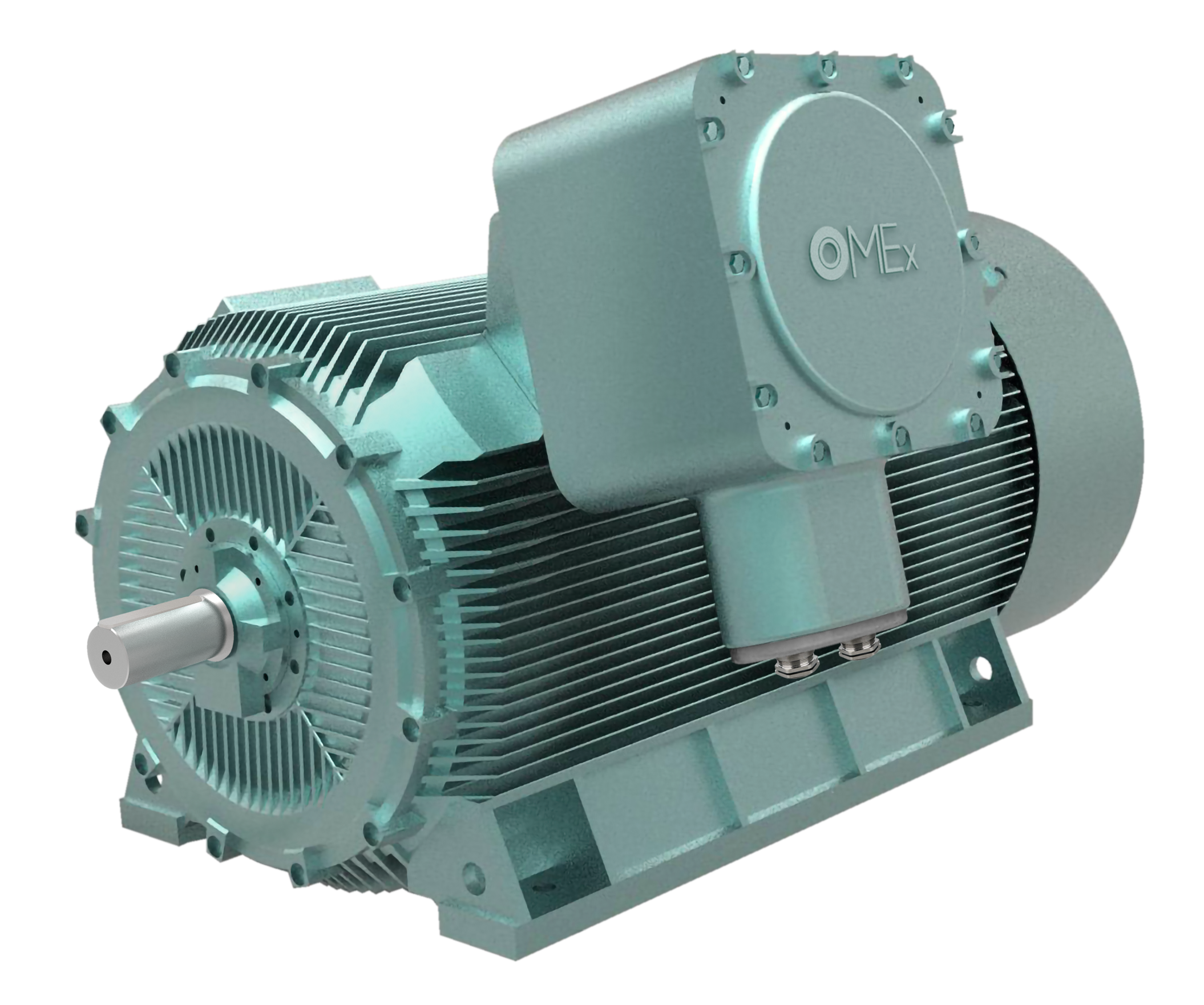

Relying on certified and guaranteed motors from OME Motors is the best way to ensure consistent performance and reduce unexpected costs due to machine downtime or extraordinary interventions.

Industrial blower motors provide competitive advantages to numerous sectors:

- Food industry, for drying processes and ingredient transport

- Water treatment and purification, where reliability and energy consumption are priorities

- Packaging, for rapid handling and cleaning operations

- Chemical and pharmaceutical industries, which require maximum safety and controlled environment management

- Paper, electronics, and plastic processing industries

For each area, having an electric motor for industrial blowers designed for the specific work cycle means reducing costs, increasing quality, and facilitating simpler and scheduled maintenance.

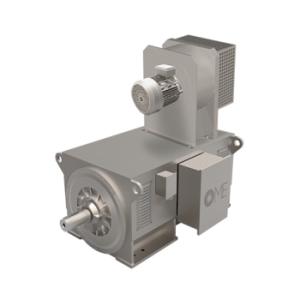

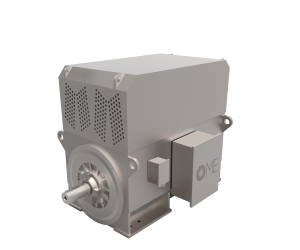

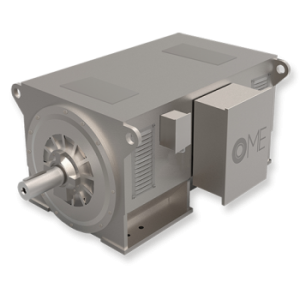

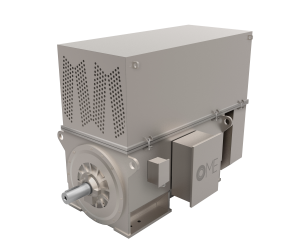

Selecting the most suitable motors for industrial blowers for your production context is a strategic choice that affects hourly costs, work quality, and corporate sustainability goals. OME Motors produces electric motors for industrial blowers that are certified, high-performing, and equipped with the most modern control systems. Trust our experts to evaluate the best solution, request a tailored consultation, and transform the way your company manages energy and air, with the assurance of a solid and innovative choice.

![]()